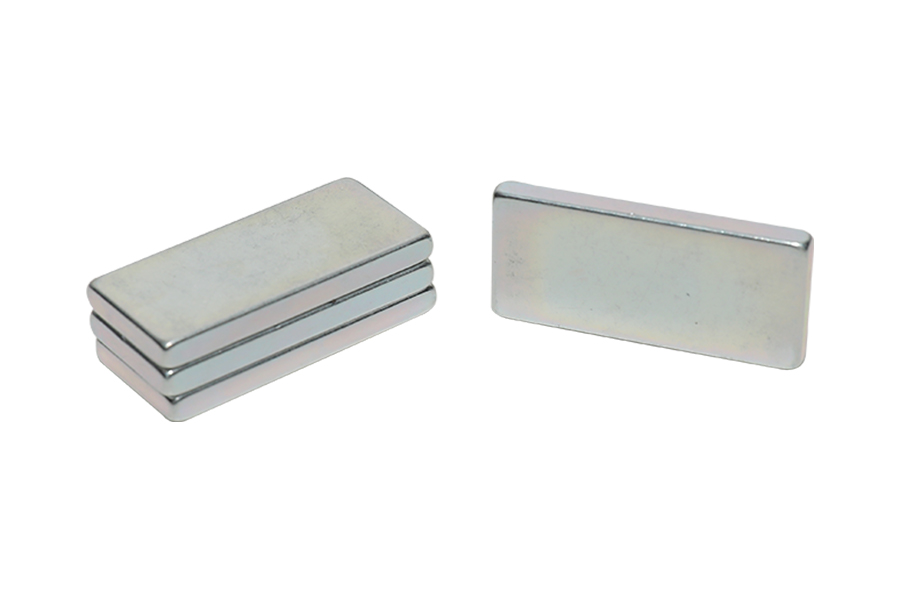

Rectangular Pure Permanent Magnet

Date:2023-03-30

A rectangular pure permanent magnet is a kind of bar magnet that has two poles, one at each end. It is a common type of magnet used in astronomical observations and in other fields of science.

Compared to electromagnets which are temporary magnets, a pure permanent magnet has high intensity and magnetic potential at its poles. It is also characterized by its ability to generate strong external magnetic field.

All magnets have two points where they generate the strongest external magnetic field, known as the north and south poles. These points are the source of a magnet's magnetic moment, which is a vector that defines a magnet's general magnetic properties.

In general, a bar magnet has a north pole at each end and a south pole. This is because the Earth's magnetic field orients itself north-south.

To produce a bar magnet, a piece of material is placed between the two poles of a very powerful electromagnet and then energized for a period of time. This will magnetize the loose powder particles within the material into groups of atoms that are called magnetic domains.

The material's individual domains are then oriented into a direction that contributes to the finished magnet's strength and coercivity. This direction is usually chosen by the designer of the magnet during the manufacturing process.

Rectangular pure permanent magnets have become an important type of magnetic material because of their strength, reversibility and low demagnetizing factor. They are used in many applications including magnetic shielding, magnetic bearings, and other devices that require high strength and very low demagnetization.

When a magnet is placed in an electric circuit, it will gradually reach saturation and then be demagnetized by the magnetic field of the circuit. This process is also called the hysteresis loop. The cycle is a function of the magnet's specific material and its operating conditions.

The reversibility of the hysteresis loop in a permanent magnet material depends on its specific property, such as its ferromagnetic or ferrimagnetic characteristics and its permeance to the magnetic field. Changes in the permeance of a magnet can cause it to fall below the knee of its hysteresis curve and lead to partial or irreversible losses.

This is why it is important to test a new magnet for its performance before using it in an application. Ideally, tests will be designed to directly inspect the critical parameters that are required by the specific application.

Typical testing includes determining the strength of the magnet, its demagnetizing factor, and the length of its magnetic domains. Several different types of testing can be used to do this.

For example, a standard measurement technique for determining the strength of a rectangular pure permanent magnet is to place it between two electrodes and then energise it in a magnetic field for a few minutes. The magnetic field of the electrodes will then be measured and compared with the magnet's actual strength.

Alternatively, a more accurate method of testing is to use a magnetic force microscope to energise the magnet and measure its magnetic moment. This will provide an exact value for the magnet's magnetic moment, and it is then possible to determine if it has the proper magnetic properties.

简体中文

简体中文 English

English Deutsche

Deutsche